Highly diverse machine facilities connected simply and digitally – Episode 5: Energy monitoring

Turn your plant – even brownfield plant – into intelligent assets for the entire company. The FORCE EDGE CONNECT connectivity layer allows you to connect systems regardless of their vintage and retrieve machine data including energy efficiency. This way, your teams can make a measurable contribution to your sustainability strategy. In this specific application, FORCAM deliberately links across to SAP’s industry use cases and, in particular, the one entitled “Intelligent Assets”. Doing so enables our joint customers to make a real contribution to the sustainability goals of the UN Strategic Development Program and the Towards a Sustainable Europe by 2030 program.

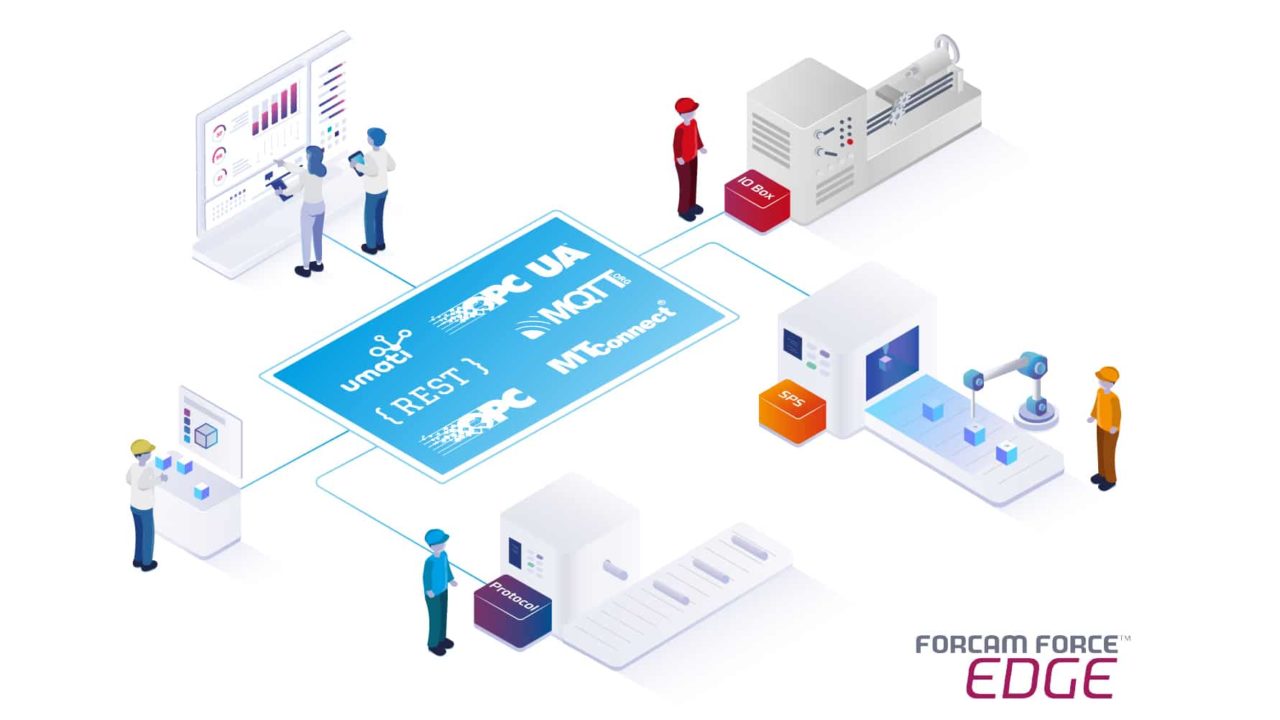

In six articles for common machine types, we outline how companies can use the FORCE EDGE CONNECT connectivity layer to connect all machines – regardless of manufacturer, vintage or control system – and process the data in the SAP DMC (Digital Manufacturing Cloud) or SAP ME/MII – e.g. in the “Intelligent Asset Network”.

Episode 5: Energy monitoring

Climate protection, sustainability, corporate governance, and costs: Resource efficiency is a top priority in business and in society at large.

Experts know that it’s in factories where value is added. Conversely, the greatest savings potential lies in production, just waiting to be tapped. Continuous improvement processes (CIPs) should therefore be part of everyday life. Data-driven manufacturing can significantly improve resource efficiency and costs.

In energy monitoring, the basic question is whether plant consumption is the main focus of attention, or whether consumption per item produced or per production order is to be recorded as an ancillary measurement. At a machine level, energy monitoring focuses primarily on the consumption of materials or energy by production plants. The key questions are:

- Which plant consumes which amounts of energy?

- At what point(s) in time do energy consumption rates occur?

Reference machine, plug-ins, process flow, target architecture

When selecting the reference asset, one should first clarify which plug-ins are relevant and should be used for communicating with the machine controller.

When considering the process, it is important to know what type of energy meter the system uses, specifically whether the meter on the plant shows an absolute figure which can be transferred directly, or whether the system has to apply the input figure incrementally.

All requirements are mapped onto the FORCAM solution portfolio. The resultant solution architecture is described as follows:

The machine measures energy consumption which is then transferred via the FORCE EDGE CONNECT plug-ins to the FORCAM machine data model for energy and process data, and is then forwarded to a third party system such as SAP DMC (Digital Manufacturing Cloud) or SAP ME/MII via the Edge API.

Autor: Marc Fröschl (Product Owner)

Your contact person

You want to learn more about the topic? As your contact person, I will be happy to answer any open questions you may have about our solutions. You can reach me at: Oliver.Hoffmann@forcam.com